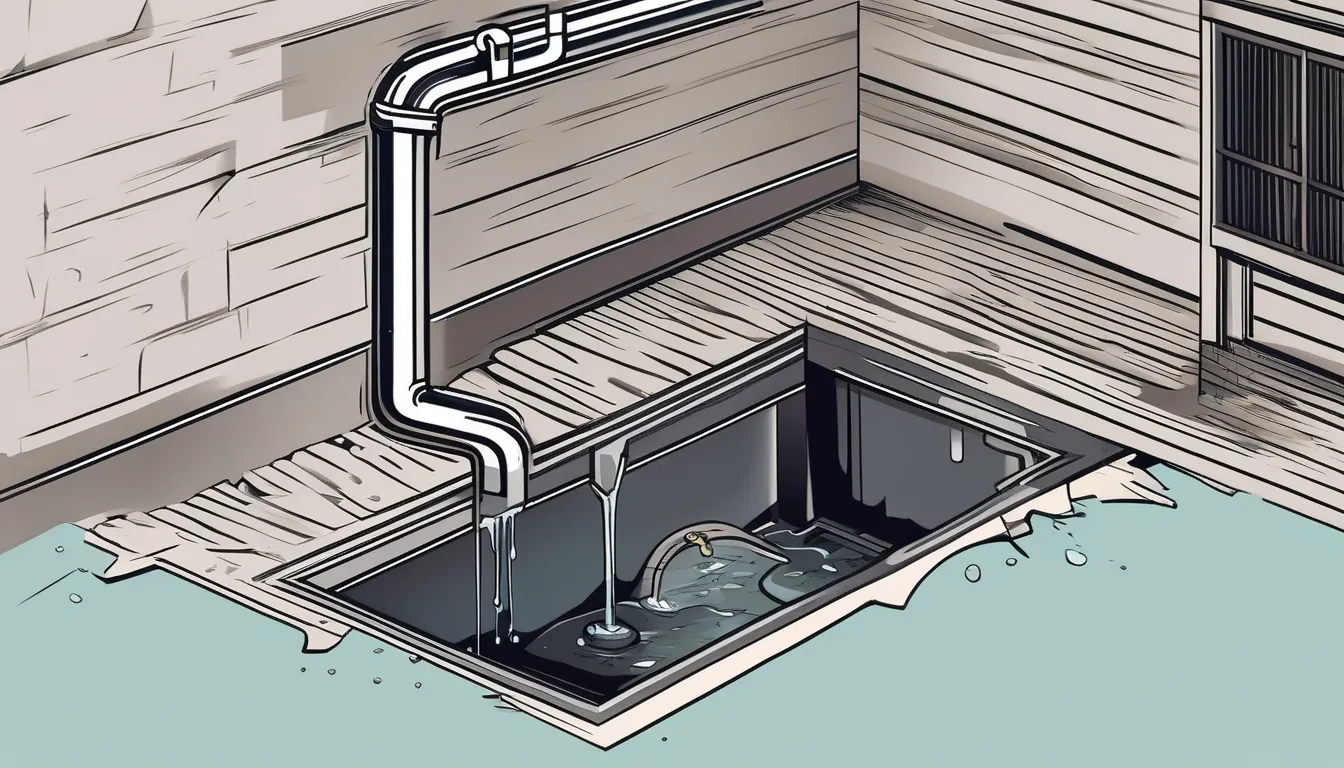

When it comes to installing drainage pipe parts, you've likely encountered or heard about common mistakes that can lead to costly repairs, property damage, or even safety hazards. While it's crucial to follow local building codes and manufacturer's instructions, you should also be aware of the most frequent errors that can occur during installation. Incorrect pipe slope and gradient, for instance, can significantly impact water flow and overall system performance. But what are the other common mistakes you should watch out for, and how can you prevent them from happening in the first place?

Common Installation Errors

Frequently, inexperienced DIYers and even seasoned professionals make the same mistakes when installing drainage pipe parts. You'll want to avoid these common errors to ensure a functional and efficient drainage system.

One of the most common mistakes is incorrect pipe slope. You're required to maintain a minimum slope of 1/4 inch per foot to allow for proper water flow. If the slope is too shallow, water will accumulate, leading to backups and clogs.

You're also likely to make mistakes during the connection process. You'll need to secure pipe connections tightly to prevent leaks. Use the correct type and number of gaskets or seals to ensure a watertight connection.

Another common error is failing to vent your drainage system. You'll need to install vents to allow air to enter the pipes and prevent the formation of vacuums. This will help to maintain the proper flow of water through the system.

Pipe Material Selection Mistakes

When selecting the right drainage pipe material, you're faced with a multitude of options, each with its own strengths and weaknesses. To avoid making costly mistakes, consider the specific requirements of your drainage system.

If you're dealing with high-pressure or high-temperature applications, you may need pipes made from durable materials like PVC or PP. On the other hand, if you're working on a budget-friendly project, you might opt for corrugated metal or clay pipes.

However, it's crucial to consider the potential drawbacks of each material. For instance, PVC pipes may be prone to cracking and damage from UV light exposure, while clay pipes can be heavy and require additional support. Corrugated metal pipes, meanwhile, may corrode over time, especially if exposed to acidic or salty water.

Slope and Gradient Issues

You've selected the right drainage pipe material, but now it's time to think about the pipe's installation. A crucial aspect of this process is ensuring the correct slope and gradient. If your drainage pipe isn't sloped properly, it can lead to poor water flow, causing backups and damage to your property.

To avoid this, you'll need to check the local building codes for the required slope and gradient. Typically, drainage pipes should have a minimum slope of 1/4 inch per foot to allow for efficient water flow.

However, this can vary depending on the pipe's diameter and the type of drainage system you're installing. It's essential to consult the manufacturer's instructions and local regulations to determine the correct slope for your specific situation.

When installing the pipe, use a level to ensure it's properly aligned and sloped. You may also need to use pipe supports or brackets to maintain the correct gradient, especially over long distances. By paying attention to the slope and gradient, you can prevent costly mistakes and ensure a well-functioning drainage system.

Joint and Connection Problems

A leaky joint or connection can quickly compromise the integrity of your drainage pipe system, leading to costly repairs and property damage. When installing drainage pipe parts, it's crucial you ensure all joints and connections are secure and watertight.

Loose connections can cause leaks, while misaligned pipes can put additional stress on the system.

To avoid joint and connection problems, use the correct type of sealant or gasket for your specific pipe material. Follow the manufacturer's instructions for application and curing times.

Also, ensure all pipes are properly aligned and supported before making connections. This is especially important for pipes that will be subject to heavy water flow or pressure.

Regularly inspect your connections for signs of wear or damage. Check for cracks in the pipe or sealant, and look for water stains or mineral deposits that can indicate leaks.

Testing and Inspection Oversights

Inspecting and testing your drainage pipe connections is only effective if you do it correctly. One common oversight isn't checking for correct slope and pitch.

If your drainage pipes aren't sloped correctly, you'll end up with clogs and backups. Make sure to check your local building codes for the recommended slope and pitch, and use a level to ensure your pipes are installed correctly.

You also need to test your 排水管 岐阜県 system under real-world conditions. Don't just run water through the pipes at a trickle; simulate heavy rainfall or flooding to see how your system handles it.

Check for leaks, clogs, and other issues that mightn't be apparent during a simple test. Additionally, use a camera or other inspection equipment to visually inspect your pipes and connections.

Another oversight isn't testing your system in sections.

Test each section of your drainage system separately to identify and fix problems before they become major issues. By doing so, you'll be able to catch and fix problems early on, saving you time and money in the long run.

Conclusion

You've made it through the common pitfalls of installing drainage pipe parts. To recap, avoiding mistakes comes down to choosing the right materials, following local building codes, and paying attention to detail. Make sure to slope your pipes correctly, secure connections tightly, and test the system thoroughly. By double-checking your work and staying vigilant, you'll be able to identify and fix issues before they become major problems, ensuring a reliable and efficient drainage system.