When you consider the efficiency of industrial processes, turbo expanders often come to mind as crucial components that convert high-pressure gas energy into useful work. You might not realize how their unique design plays a significant role in optimizing various applications, from natural gas processing to cryogenics. As industries strive for greater sustainability and cost-effectiveness, the importance of turbo expanders continues to grow. But what specific benefits do they offer, and how are they evolving to meet future demands? Let’s explore these questions further.

What Is a Turbo Expander?

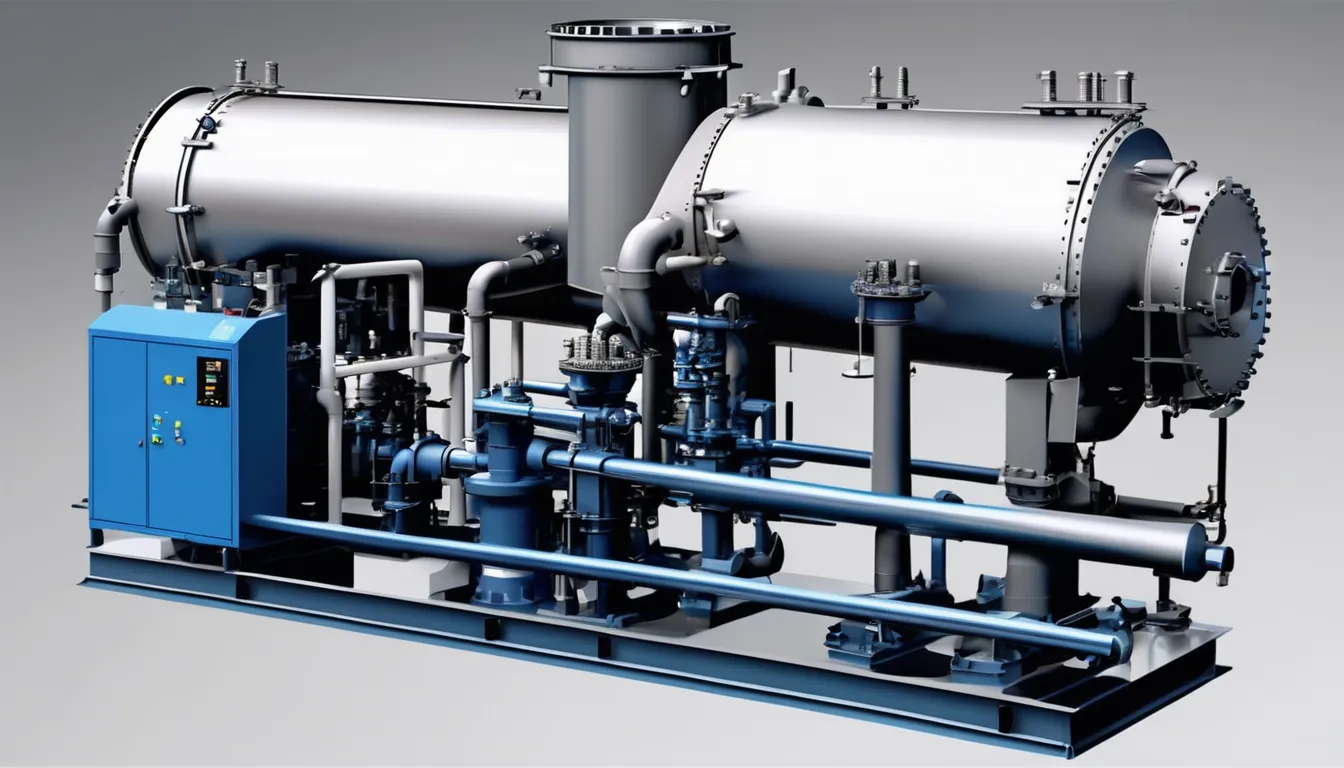

A turbo expander is a mechanical device that converts the energy of high-pressure gas into useful work, typically in the form of rotational energy. You’ll find Turbo Expander s used in various industrial applications, where they help improve energy efficiency and reduce operational costs.

These devices are particularly valuable in processes where gas expands rapidly, such as in natural gas processing, cryogenics, and power generation.

In operation, high-pressure gas enters the turbo expander, causing it to spin. This spinning motion drives a generator or other machinery, converting gas energy into electricity or mechanical work. You can visualize this process as similar to a wind turbine, where kinetic energy is harnessed to produce power.

Turbo expanders come in different designs, including radial and axial configurations, each suited to specific applications and pressure ranges. Their ability to operate under extreme conditions makes them versatile tools in industries like oil and gas, food processing, and refrigeration.

Principles of Turbo Expansion

Turbo expansion relies on fundamental thermodynamic principles to convert high-pressure gas energy into mechanical work. You’ll find that this process involves a series of steps that optimize energy extraction while minimizing losses.

Here’s a breakdown of how it works:

- Pressure Drop: The high-pressure gas enters the turbine, undergoing a significant pressure drop, which leads to a decrease in temperature.

- Expansion: As the gas expands, it accelerates through the turbine blades. This transformation of energy happens rapidly, allowing the gas to perform work on the blades.

- Mechanical Work Generation: The rotating turbine generates mechanical energy, which can be harnessed to power generators or compressors. This step is crucial for improving overall system efficiency.

- Energy Recovery: Finally, the lower-pressure gas exits the expander, often at a temperature suitable for further industrial processes, allowing for the recovery of energy that can be reused.

Understanding these principles is essential for effectively utilizing turbo expanders in various applications.

Key Industrial Applications

In various industrial sectors, turbo expanders play a pivotal role in enhancing energy efficiency and reducing operational costs. You’ll find these devices primarily in natural gas processing, where they help extract valuable energy from high-pressure gas streams. By expanding the gas, turbo expanders convert its pressure energy into mechanical energy, which can be used to power compressors or generators.

Another key application is in cryogenic processes, particularly in liquefied natural gas (LNG) plants. Here, turbo expanders enable the cooling of gases to extremely low temperatures, facilitating the liquefaction process. This is essential for transportation and storage, as LNG takes up significantly less space than gaseous forms.

In the petrochemical industry, turbo expanders find use in various processes, including gas recovery and power generation. They help optimize operations by harnessing waste energy, contributing to more sustainable practices.

Lastly, in geothermal energy applications, you can employ turbo expanders to convert steam energy into electricity, making them crucial for maximizing energy extraction from geothermal resources.

Benefits of Using Turbo Expanders

One of the key benefits of using turbo expanders is their ability to significantly enhance energy efficiency in industrial processes. By harnessing the energy from expanding gases, you can convert it into useful work, reducing overall energy consumption. This not only saves you money but also lowers your carbon footprint.

Here are some additional benefits that might interest you:

- Cost Reduction: Turbo expanders can lead to lower operational costs by maximizing energy recovery, which translates to savings on fuel and energy bills.

- Improved Process Stability: They help maintain stable operating conditions, which can enhance product quality and reduce downtime caused by fluctuations.

- Compact Design: Turbo expanders often have a smaller footprint compared to traditional equipment, allowing for more efficient use of space in your facility.

- Versatility: You can apply turbo expanders in various applications, including gas processing, refrigeration, and power generation, making them a versatile choice for multiple industries.

Incorporating turbo expanders into your processes can yield significant long-term benefits, helping you stay competitive in today’s market.

Future Trends in Turbo Expansion

As industries look to optimize energy recovery and reduce operational costs, the future of turbo expansion technology is poised for exciting advancements.

You’ll find that increasing energy efficiency will be a primary focus, with innovations aimed at enhancing the performance of turbo expanders. Expect to see developments in materials and design that allow for higher operational pressures and temperatures, driving greater efficiency in energy recovery systems.

You should also keep an eye on digitalization trends, as smart sensors and IoT integration will play a significant role in monitoring performance and predictive maintenance. This means fewer unexpected downtimes and more streamlined operations.

Furthermore, advancements in computational fluid dynamics are set to refine the design process, allowing for more tailored solutions to specific industrial needs.

As industries become more environmentally conscious, you might notice a shift towards turbo expanders that align with sustainability goals. These systems will likely integrate with renewable energy sources, enhancing their role in reducing carbon footprints.

Conclusion

In conclusion, turbo expanders play a crucial role in enhancing energy efficiency across various industrial sectors. By converting high-pressure gas energy into rotational energy, they optimize processes and improve product quality. As industries continue to focus on sustainability and cost reduction, the importance of turbo expanders will only grow. Embracing these technologies now will position you at the forefront of innovation, ensuring your operations remain competitive and environmentally friendly in the future.